If there was ever a field that offers remarkable opportunities for a successful and rewarding career, that would be a career in the logistics field. As supply chain management becomes more and more specialized, professionals of all ages will find a plethora of opportunities available to them when it comes to developing their career. Here we offer a few key skills that are crucial for success in this field – no matter your position in the field.

Problem Solving

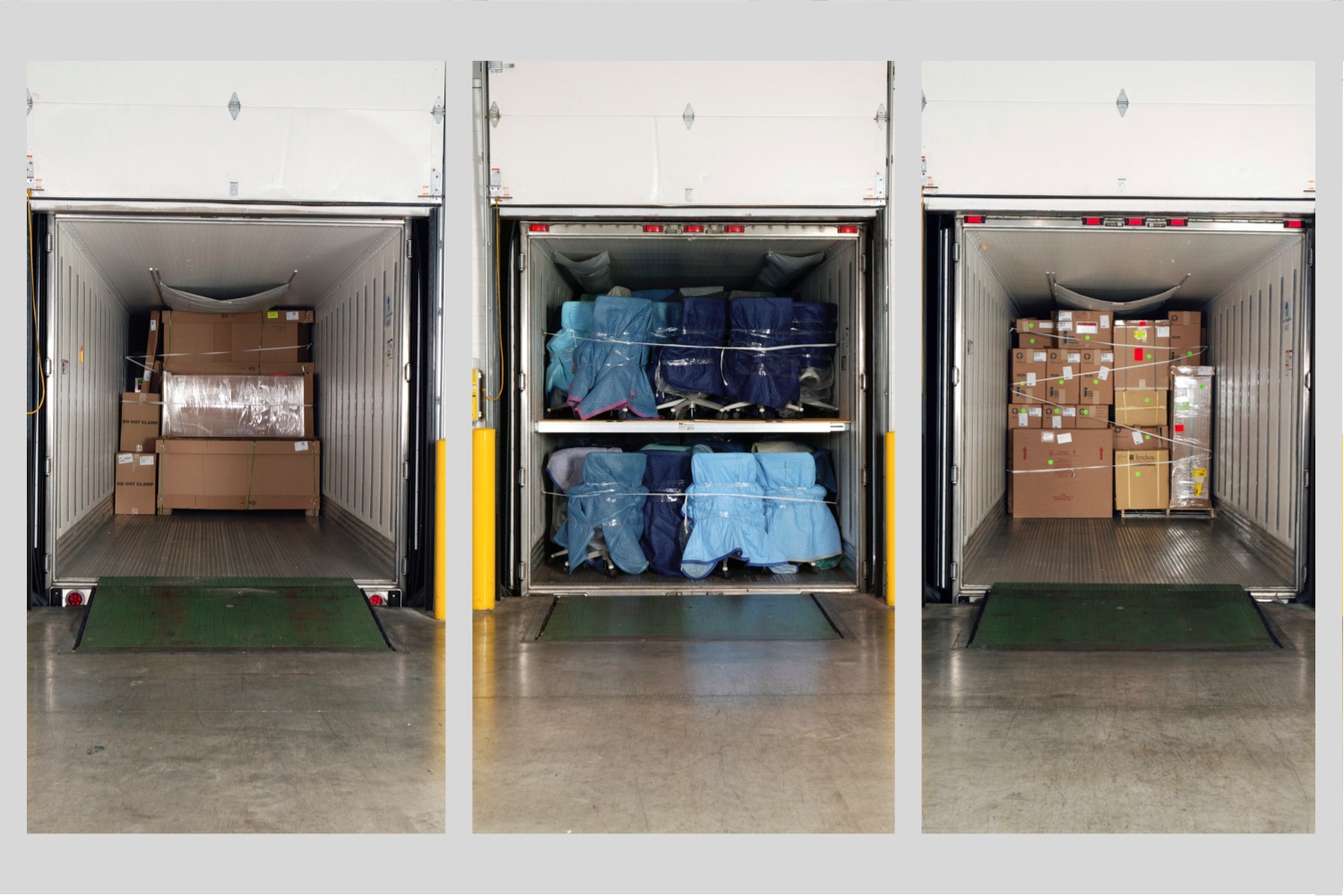

Whether a customer’s problems involve how to get a shipment to its destination on time and undamaged, how to pack a trailer effectively, or assisting with a localized sourcing plan, there is no shortage of problem solving opportunities available. The best problem solvers approach this with the customer in mind, providing them with the best possible solutions to their problems. Collaboration is also an invaluable skill involved in problem solving since multiple ideas can help find the best solution.

Communication

Communication skills are vital to success in the logistics field. Being able to communicate with customers about successes, delays, and difficulties is crucial in building a relationship with every member of the supply chain. Logistics is a field that is built upon relationships and honesty is a central component to those relationships. If companies cannot trust one another, then the supply chain can fall apart. It is never worth covering up with a white lie. Trust is far too valuable when it comes to managing a customer’s shipments.

Innovation

While some say that innovation cannot be taught, we believe otherwise. Innovation is not always about technological improvements. Sometimes innovation involves developing ways of helping the customer, creating more efficient processes or ways to keep the campus clean. Technology helps, but it’s not the only means of improving a company. Focusing on helping customers, drivers and other members of the organization is just as, if not more valuable in the long run. Innovation is about making things better for an organization and creating a dynamic work environment for everyone.

Here at Zip Xpress, we understand the importance of professional development. While the outlined skills above may seem cliche, their importance cannot be overstated. These are all skills that can be learned and developed by every member of the organization, showing that everyone can contribute to our value as a company. These skills are an ongoing process of development here at Zip Xpress and it’s why we’re able to maintain a 99% satisfaction rate with all of our customers and focus on creating an exceptional company culture. If you know someone who wants to further their career in the logistics industry, please let us know. To see how our incredible employees can create a custom carrier solution that is right for your business, start today with Zip Xpress!