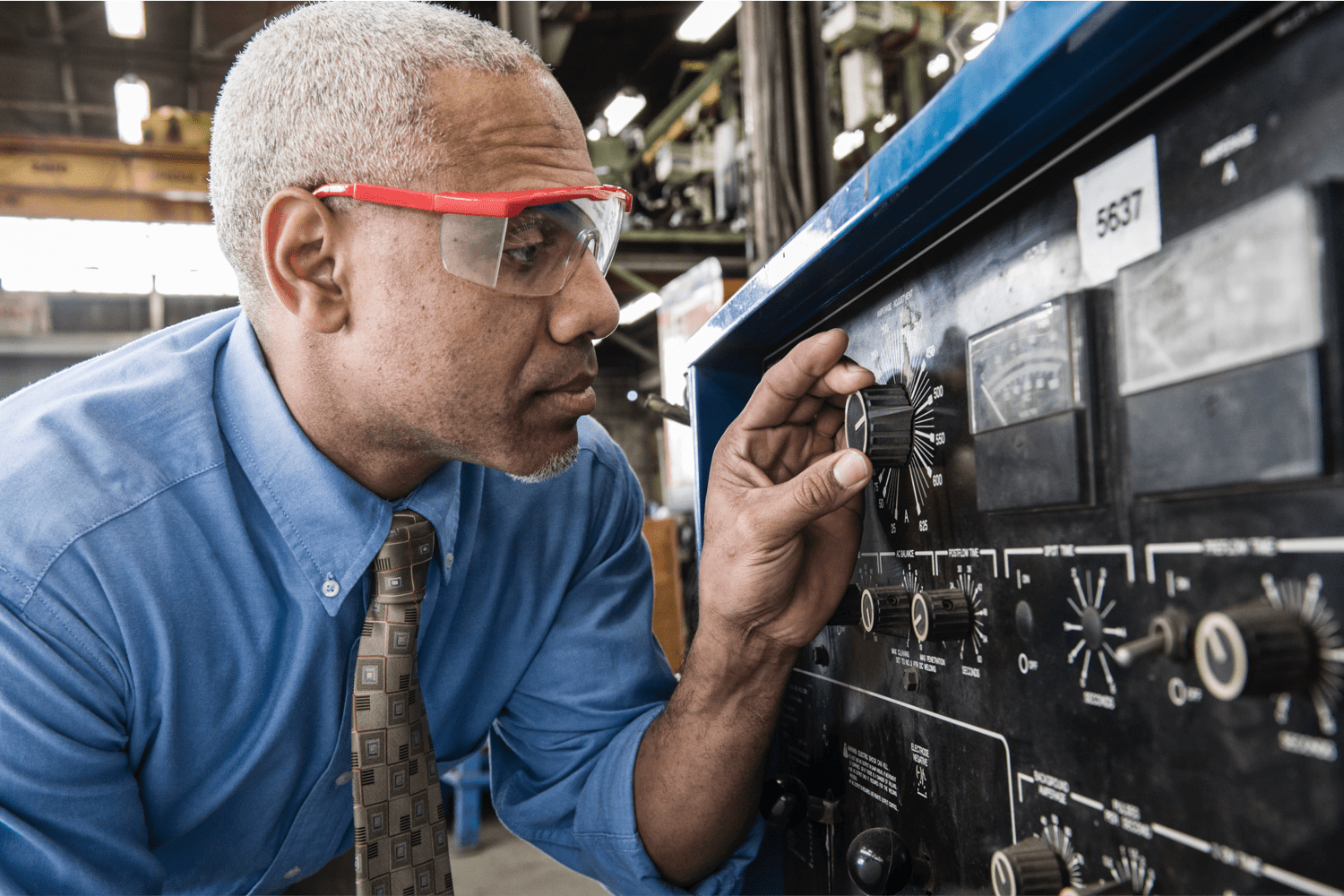

Supply chains are complex and often fickle parts of doing business, but they are integral to the success of any manufacturer. The quality and efficiency of an internal supply chain can make or break a company, so it is important to run a well-oiled machine. However, there are many challenges when it comes to expanding your supply chain. Moving too quickly could lead to unnecessary costs, but waiting too long could put a lot of stress on your operations.

Expanding your supply chain could come with a variety of actions. Perhaps you need to build new warehouses to accommodate increased inventories or new product lines. It could also mean adding more back office workers to set up and operate newer, sophisticated IT systems. In any case, you want to do so only when the time is right. Inventory forecasting and analytics can help you determine whether or not you need to expand well ahead of time. And while you can’t expect 100% accuracy, you can get a good idea of where your company is headed by taking a proactive approach.

In addition to knowing when to expand your supply chain, you also need to know how to expand it. A trusted carrier can assist with this since they can help you expand into markets you wouldn’t normally have access to. Expanding your supply chain may focus more on an improved internal and external trucking network as well as extended hours to accommodate more dock shifts. You may even have a need for additional warehouse space if you’re increasing production, but as you can see many of these circumstances are a case by case basis.

At Zip Xpress, we understand that great service is the key to expanding a supply chain. A trusted carrier can help you expand and compete in distant markets as well as provide for you the options that will work with your business in expanding your supply chain. At Zip Xpress, we refer to these options as custom carrier solutions and we’ve helped many companies go from regional to national supply chains, providing access to the West Coast and beyond. To see what custom carrier solutions we can create for your business, start today with Zip Xpress!